Facilities

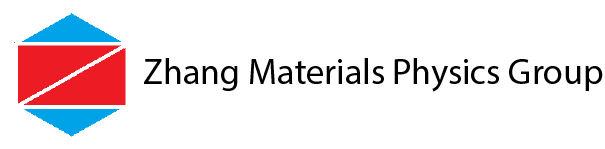

Pulsed Laser Deposition System

Our COMPex 102 Flourine laser can produce laser pulses up to 10 Hz. This is used to heat the desired target and evaporate small amounts into the environment in the growth chamber, which then deposit on substrates in a uniform fashion. This process can be monitored with the attached Reflection High Energy Electron Diffraciton (RHEED) apparatus. Growth of films can be accomplished both at UHV and under O2 pressure.

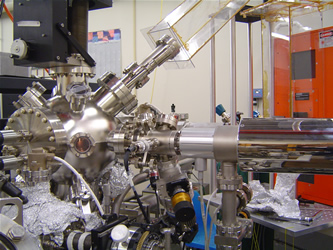

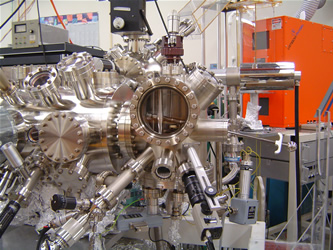

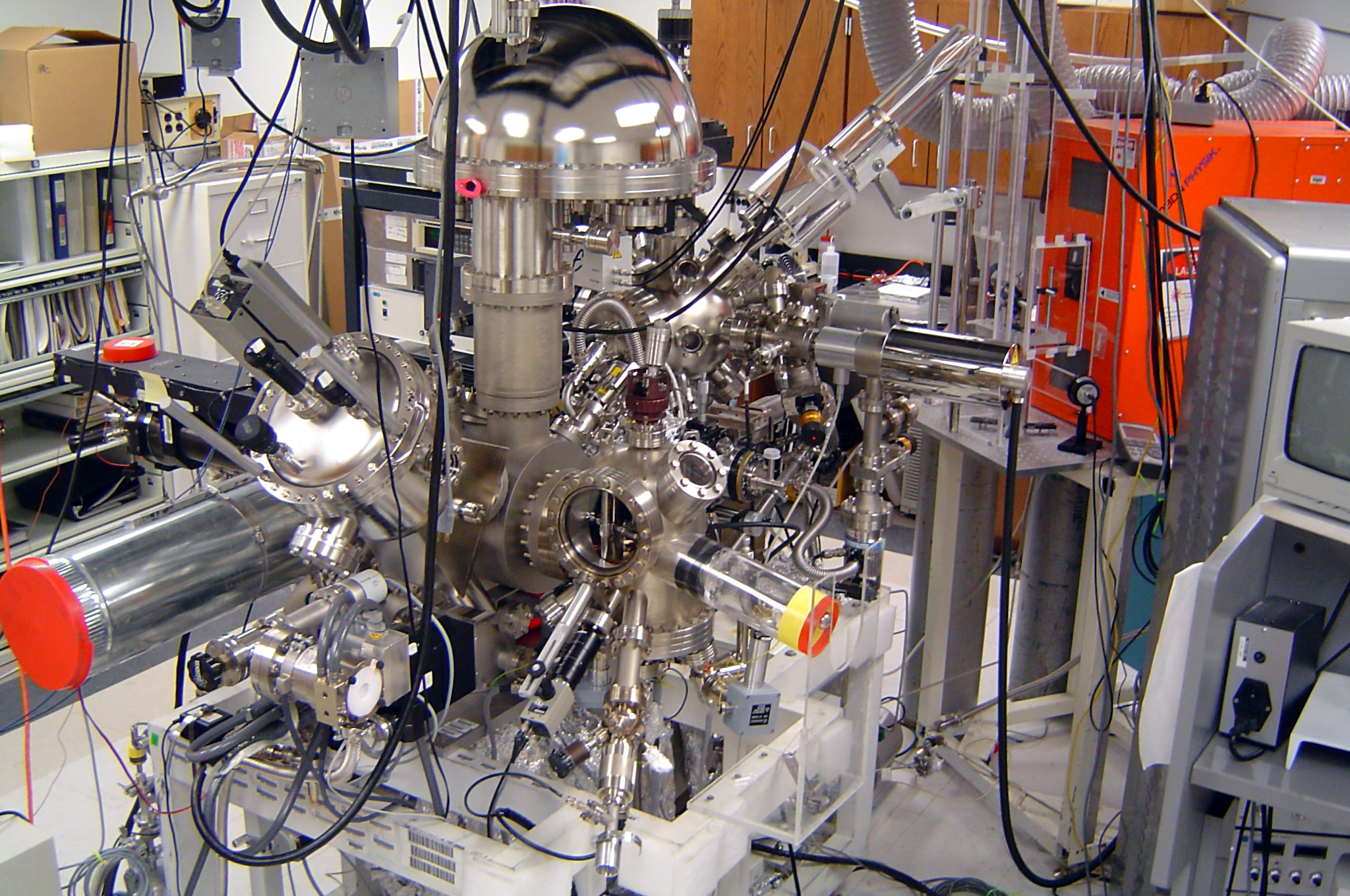

Scanning Tunneling Microscope (STM)

Our Omicron system allows for mapping of material's surface morphology, as well as determining local electroning properties. Can be performed down to 100 K.

X-Ray Photoemmision Spectroscopy (XPS)

By radiating samples with X-ray light, their chemical composition, as well as oxidation states, near the surfaces can be determined. This system also includes UPS and has the option for angle-resolved XPS, which allows us to probe different depths of the thin films grown.

Low Energy Electron Diffraction (LEED)

LEED can be used to probe the surface crystal structure of single crystals or in-situ grown thin films. All characterization methods in the main chamber are carried out at UHV (~10^-10 torr) and can take place at temperatures down to 100K.

In-situ growth and characterization

Our system is capable of both high quality PLD film growth and meaningful characterization of single crystals, thin films, and heterostructures. All of this can be done under Ultra-High Vacuum, from growth through measurement, which allows us to probe phenomena that would otherwise be lost using other systems.